Boston College’s robotic MAMA BEAR autonomously creates and checks energy-absorbing buildings, lately attaining a file 75% effectivity, with functions starting from transport supplies to navy gear. Credit score: Devin Hahn, Boston College Productions

An autonomous robotic created a shock-absorbing form no human ever may. Be taught what it means for designing safer helmets, packaging, automobile bumpers, and extra.

Inside the confines of a lab in Boston College’s Faculty of Engineering, a robotic arm drops small, plastic objects right into a field exactly positioned on the ground to catch them as they fall. One after the other, these tiny object—feather-light, cylindrical items, no greater than an inch tall—fill the field. Some are blue, others pink, purple, inexperienced, or black.

Every of those buildings is the results of an experiment in robotic autonomy. Working independently and adapting by ongoing studying, the robotic is on a quest to create probably the most environment friendly energy-absorbing form to ever exist.

The Strategy of Innovation

To do that, the robotic creates a small plastic construction with a 3D printer, information its form and dimension, strikes it to a flat metallic floor—after which crushes it with a stress equal to an grownup Arabian horse standing on 1 / 4. The robotic then measures how a lot vitality the construction absorbed, how its form modified after being squashed, and information each element in an unlimited database.

Then, it drops the crushed object into the field and wipes the metallic plate clear, able to print and check the following piece. It will likely be ever-so-slightly totally different from its predecessor, its design and dimensions tweaked by the robotic’s laptop algorithm based mostly on all previous experiments—the idea of what’s referred to as Bayesian optimization. Experiment after experiment, the 3D buildings get higher at absorbing the affect of getting crushed.

Inside a lab in Boston College’s Faculty of Engineering, a robotic arm drops small, plastic objects right into a field positioned completely on the ground to catch them as they fall. One after the other, these tiny buildings—feather-light, cylindrical items, no greater than an inch tall—fill the field. Some are pink, others blue, purple, inexperienced, or black. Every object is the results of an experiment in robotic autonomy. By itself, studying because it goes, the robotic is trying to find, and making an attempt to make, an object with probably the most environment friendly energy-absorbing form to ever exist. Credit score: Devin Hahn, Boston College Productions

Steady Enchancment and Functions

These relentless iterations are potential due to the work of Keith Brown, an ENG affiliate professor of mechanical engineering, and his group within the KABlab. The robotic, named MAMA BEAR—brief for its prolonged full title, Mechanics of Additively Manufactured Architectures Bayesian Experimental Autonomous Researcher—has developed because it was first conceptualized by Brown and his lab in 2018. By 2021, the lab had set the machine on its quest to make a form that absorbs probably the most vitality, a property referred to as its mechanical vitality absorption effectivity. This present iteration has run repeatedly for over three years, filling dozens of packing containers with greater than 25,000 3D-printed buildings.

Sensible Implications and Achievements

Why so many shapes? There are numerous makes use of for one thing that may effectively soak up vitality—say, cushioning for delicate electronics being shipped the world over or for knee pads and wrist guards for athletes. “You would draw from this library of knowledge to make higher bumpers in a automobile, or packaging gear, for instance,” Brown says.

To work ideally, the buildings must strike the right stability: they’ll’t be so robust that they trigger injury to no matter they’re supposed to guard, however needs to be robust sufficient to soak up affect. Earlier than MAMA BEAR, the perfect construction anybody ever noticed was about 71 % environment friendly at absorbing vitality, says Brown. However on a cold January afternoon in 2023, Brown’s lab watched their robotic hit 75 % effectivity, breaking the identified file. The outcomes had been simply revealed immediately (Could 21) within the journal Nature Communications.

“After we began out, we didn’t know if there was going to be this record-breaking form,” says Kelsey Snapp (ENG’25), a PhD scholar in Brown’s lab who oversees MAMA BEAR. “Slowly however absolutely we saved inching up, and broke by.”

Report-Breaking Design and Additional Improvements

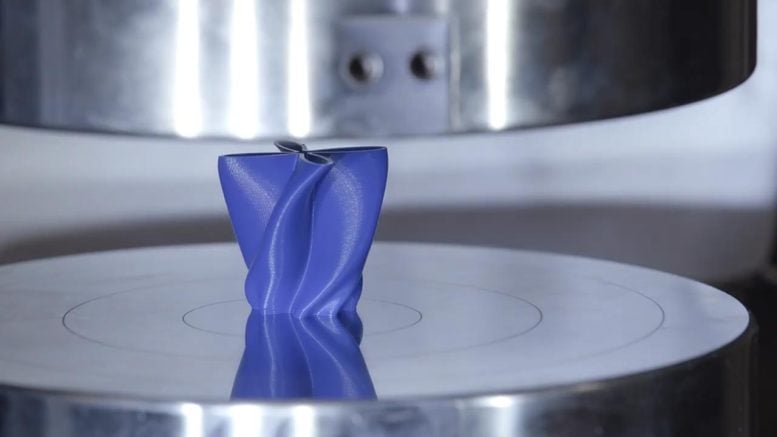

The record-breaking construction appears like nothing the researchers would have anticipated: it has 4 factors, formed like skinny flower petals, and is taller and narrower than the early designs.

“We’re excited that there’s a lot mechanical information right here, that we’re utilizing this to be taught classes about design extra usually,” Brown says.

Their intensive information is already getting its first real-life utility, serving to to tell the design of latest helmet padding for US Military troopers. Brown, Snapp, and undertaking collaborator Emily Whiting, a BU Faculty of Arts & Sciences affiliate professor of laptop science, labored with the US Military and went by discipline testing to make sure helmets utilizing their patent-pending padding are comfy and supply ample safety from affect. The 3D construction used for the padding is totally different from the record-breaking piece—with a softer heart and shorter stature to assist with consolation.

The Increasing Position of Autonomous Robots in Analysis

MAMA BEAR isn’t Brown’s solely autonomous analysis robotic. His lab has different “BEAR” robots performing totally different duties—just like the nano BEAR, which research the way in which supplies behave on the molecular scale utilizing a expertise referred to as atomic drive microscopy. Brown has additionally been working with Jörg Werner, an ENG assistant professor of mechanical engineering, to develop one other system, referred to as the PANDA—brief for Polymer Evaluation and Discovery Array—BEAR to check 1000’s of skinny polymer supplies to seek out one which works greatest in a battery.

“They’re all robots that do analysis,” Brown says. “The philosophy is that they’re utilizing machine studying along with automation to assist us do analysis a lot quicker.”

“Not simply quicker,” provides Snapp. “You are able to do stuff you couldn’t usually do. We will attain a construction or aim that we wouldn’t have been capable of obtain in any other case, as a result of it could have been too costly and time-consuming.” He has labored intently with MAMA BEAR because the experiments started in 2021, and gave the robotic its skill to see—referred to as machine imaginative and prescient—and clear its personal check plate.

The Way forward for Autonomous Analysis

The KABlab is hoping to additional show the significance of autonomous analysis. Brown needs to maintain collaborating with scientists in numerous fields who want to check extremely giant numbers of buildings and options. Despite the fact that they already broke a file, “now we have no skill to know if we’ve reached the utmost effectivity,” Brown says, that means they might presumably break it once more. So, MAMA BEAR will carry on working, pushing boundaries additional, whereas Brown and his group see what different functions the database might be helpful for. They’re additionally exploring how the greater than 25,000 crushed items might be unwound and reloaded into the 3D printers so the fabric might be recycled for extra experiments.

“We’re going to maintain finding out this technique, as a result of mechanical effectivity, like so many different materials properties, is barely precisely measured by experiment,” Brown says, “and utilizing self-driving labs helps us decide the perfect experiments and carry out them as quick as potential.”

Reference: “Superlative mechanical vitality absorbing effectivity found by self-driving lab-human partnership” 21 Could 2024, Nature Communications.

DOI: 10.1038/s41467-024-48534-4