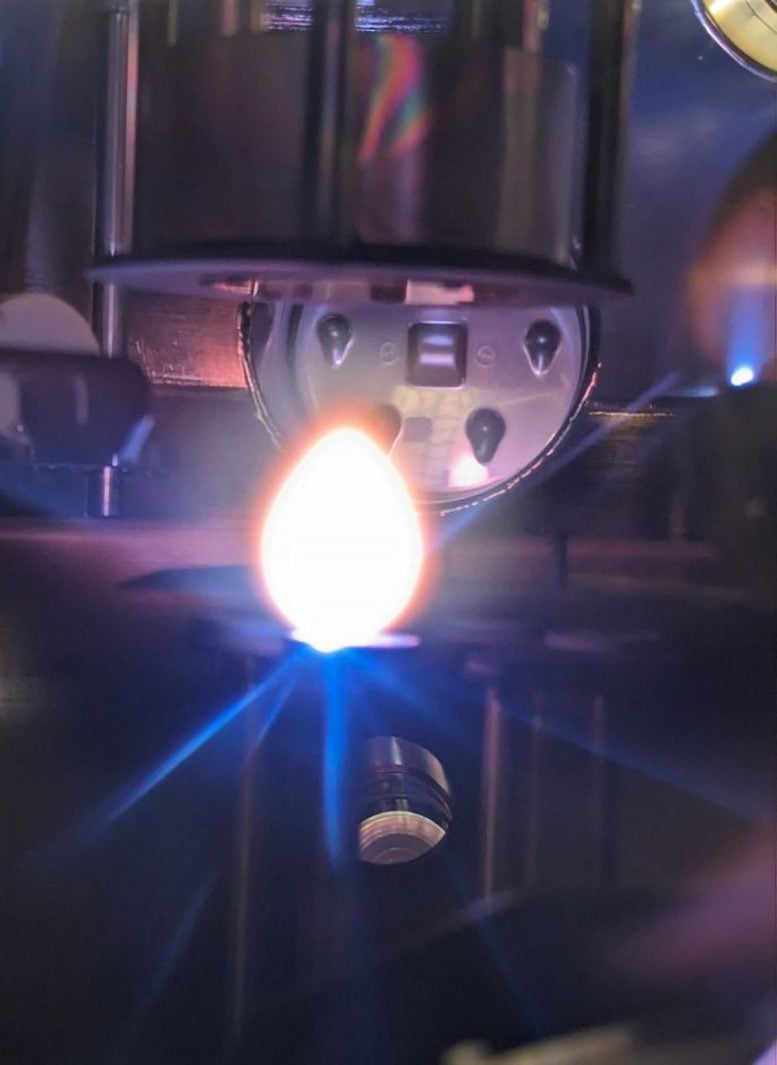

Pulsed laser deposition, through which a laser beam ablates a fabric that’s deposited as a movie on a substrate, was used to manufacture the HTS wires. Credit score: College at Buffalo

New analysis reveals that the large-scale, cost-effective implementation of high-temperature superconducting wire is more and more possible.

The way forward for our power techniques may very well be formed by high-temperature superconducting (HTS) wires. These superior supplies, able to transmitting electrical energy with out resistance at greater temperatures than typical superconductors, have the potential to remodel the electrical grid and make business nuclear fusion a actuality.

But these large-scale purposes gained’t occur till HTS wires will be fabricated at a price-performance metric equal to that of the plain copper wire bought at your native ironmongery store.

New University at Buffalo-led analysis is shifting us nearer to that purpose. In a research printed in Nature Communications, researchers report that they’ve fabricated the world’s highest-performing HTS wire section whereas making the price-performance metric considerably extra favorable.

Based mostly on rare-earth barium copper oxide (REBCO), their wires achieved the very best essential present density and pinning power — the quantity {of electrical} present carried and talent to pin down magnetic vortices, respectively — reported so far for all magnetic fields and temperatures from 5 kelvin to 77 kelvin.

This temperature vary remains to be extraordinarily chilly — minus 451 levels to minus 321 levels Fahrenheit — however greater than the absolute zero that conventional superconductors perform at.

“These outcomes will assist information business towards additional optimizing their deposition and fabrication situations to considerably enhance the price-performance metric in business coated conductors,” says the research’s corresponding creator, Amit Goyal, PhD, SUNY Distinguished Professor and SUNY Empire Innovation Professor within the Division of Chemical and Organic Engineering, throughout the UB College of Engineering and Utilized Sciences. “Making the price-performance metric extra favorable is required to completely understand the quite a few large-scale, envisioned purposes of superconductors.”

HTS wires have many purposes

Purposes of HTS wires embody power era, resembling doubling energy generated from offshore wind turbines; grid-scale superconducting magnetic energy-storage techniques; power transmission, such because the loss-less transmission of energy in excessive present DC and AC transmission strains; and power effectivity within the type of extremely environment friendly superconducting transformers, motors and fault-current limiters for the grid.

Only one area of interest software of HTS wires, business nuclear fusion, has the potential for era of limitless clear power. In simply the previous couple of years, roughly 20 non-public firms have been based globally to develop business nuclear fusion, and billions of {dollars} have been invested in creating HTS wires for this software alone.

Different purposes of HTS wires embody next-generation MRI for drugs, next-generation nuclear magnetic resonance (NMR) for drug discovery, and high-field magnets for quite a few physics purposes. There are additionally quite a few protection purposes, resembling within the improvement of all-electric ships and all-electric airplanes.

Presently, most firms world wide fabricating kilometer-long, high-performance HTS wires use a number of of the platform technological improvements developed beforehand by Goyal and his staff.

These embody rolling assisted biaxially textured substrates (RABiTS) know-how, LMOe-enabled ion-beam assisted deposition (IBAD) MgO know-how, and nanocolumnar defects at nanoscale spacings through simultaneous phase-separation and strain-driven self-assembly know-how.

World-record essential present density and pinning power

Within the current work reported in Nature Communications, Goyal’s group reviews on ultra-high efficiency, REBCO-based superconducting wires.

At 4.2 kelvin, the HTS wires carried 190 million amps per sq. centimeter with none exterior magnetic area, also referred to as self-field, and 90 million amps per sq. centimeter with a magnetic area of seven tesla.

At a hotter temperature of 20 kelvin – the envisioned software temperature for business nuclear fusion – the wires may nonetheless carry over 150 million amps per sq. centimeter self-field and over 60 million amps per sq. centimeter at 7 tesla.

By way of essential present, this corresponds to a 4-millimeter-wide wire section at 4.2 kelvin having a supercurrent of 1,500 amps at self-field and 700 amps at 7 tesla. At 20 kelvin, it’s 1,200 amps at self-field and 500 amps at 7 tesla.

It’s price noting that the staff’s HTS movie, regardless of being solely 0.2 microns thick, can carry a present corresponding to that of economic superconducting wires with HTS movie virtually 10 instances thicker.

As for pinning power, the wires confirmed a powerful potential to carry magnetic vortices pinned or in place, with forces of about 6.4 teranewtons per cubic meter at 4.2 kelvin and about 4.2 teranewton per cubic meter at 20 kelvins, each below a 7-tesla magnetic area.

These are the very best values of essential present density and pinning power reported so far for all magnetic fields and working temperatures from 5 kelvin to 77 kelvin.

“These outcomes reveal that vital efficiency enhancements are nonetheless doable and therefore the related discount in price that might probably be realized in optimized, business HTS wires,” Goyal says.

How high-performance wire was fabricated

The HTS wire section was fabricated on substrates utilizing the (IBAD) MgO know-how and utilizing the nanocolumnar defects through simultaneous phase-separation and strain-driven self-assembly know-how. The self-assembly know-how permits incorporation on insulating or non-superconducting nanocolumns at nan0scale spacings throughout the superconductor. These nanodefects can pin the superconducting vortices, permitting for greater supercurrents.

“The excessive essential present density was made doable by a mixture of pinning results from rare-earth doping, oxygen-point defects, and insulating barium zirconate nanocolumns and their morphologies,” Goyal says.

“The HTS movie was made utilizing a complicated pulsed laser deposition system through cautious management of deposition parameters,” provides Rohit Kumar, a postdoctoral fellow within the UB Laboratory for Heteroepitaxial Progress of Practical Supplies and Gadgets, which Goyal leads.

In pulsed laser deposition, a laser beam impinges on a goal materials and ablates materials that’s deposited as a movie on an appropriately positioned substrate.

“We additionally performed atomic-resolution microscopy utilizing probably the most superior microscopes on the Canadian Heart for Electron Microscopy at McMaster College for characterization of nanocolumnar and atomic-scale defects and in addition performed some superconducting property measurements on the Università di Salerno in Italy,” Goyal says.

Reference: “Considerably enhanced essential present density and pinning power in nanostructured, (RE)BCO-based, coated conductor” by A. Goyal, R. Kumar, H. Yuan, N. Hamada, A. Galluzzi and M. Polichetti, 7 August 2024, Nature Communications.

DOI: 10.1038/s41467-024-50838-4

The Workplace of Naval Analysis (ONR) supported this basic analysis towards improvement of superior HTS wires. Goyal is the principal investigator on the mission.