Researchers have utilized AI to uncover new insights into dislocations in polycrystalline supplies, difficult present scientific fashions and paving the best way for enhanced materials efficiency in electronics and photo voltaic cells. Credit score: SciTechDaily.com

Scientists at Nagoya College in Japan have used synthetic intelligence to find a brand new methodology for understanding small defects referred to as dislocations in polycrystalline supplies, supplies extensively utilized in data gear, photo voltaic cells, and digital gadgets, that may cut back the effectivity of such gadgets. The findings had been revealed within the journal Superior Supplies.

The Problem of Polycrystalline Supplies

Virtually each machine that we use in our fashionable lives has a polycrystal element. Out of your smartphone to your pc to the metals and ceramics in your automotive. Regardless of this, polycrystalline supplies are robust to make the most of due to their complicated constructions. Together with their composition, the efficiency of a polycrystalline materials is affected by its complicated microstructure, dislocations, and impurities.

A significant downside with utilizing polycrystals in business is the formation of tiny crystal defects brought on by stress and temperature modifications. These are often called dislocations and may disrupt the common association of atoms within the lattice, affecting electrical conduction and total efficiency. To scale back the possibilities of failure in gadgets that use polycrystalline supplies, you will need to perceive the formation of those dislocations.

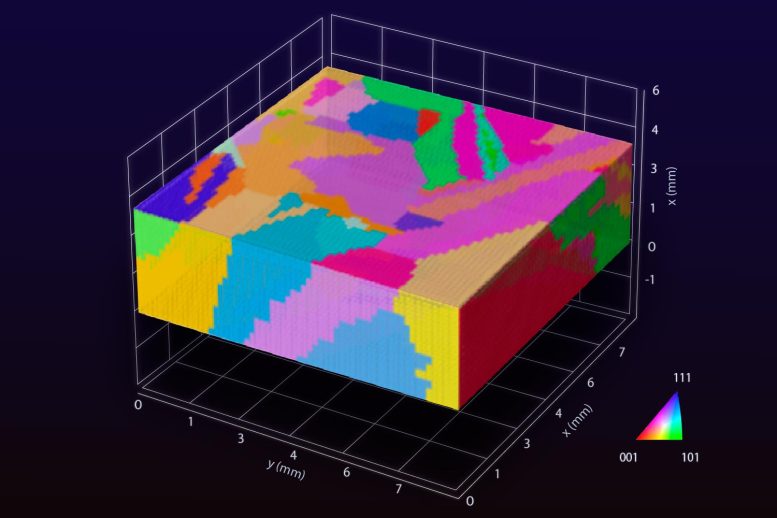

Researchers used 3D fashions created by AI to grasp complicated polycrystalline supplies which can be utilized in our on a regular basis digital gadgets. Credit score: Kenta Yamakoshi

AI-Pushed Discovery

A staff of researchers at Nagoya College, led by Professor Noritaka Usami and together with Lecturer Tatsuya Yokoi and Affiliate Professor Hiroaki Kudo and collaborators, used a brand new AI to investigate picture information of a fabric extensively utilized in photo voltaic panels, referred to as polycrystalline silicon. The AI created a 3D mannequin in digital house, serving to the staff to determine the areas the place dislocation clusters had been affecting the fabric’s efficiency.

After figuring out the areas of the dislocation clusters, the researchers used electron microscopy and theoretical calculations to grasp how these areas fashioned. They revealed stress distribution within the crystal lattice and located staircase-like constructions on the boundaries between the crystal grains. These constructions seem to trigger dislocations throughout crystal development. “We discovered a particular nanostructure within the crystals related to dislocations in polycrystalline constructions,” Usami mentioned.

Implications for Crystal Development Science

Together with its sensible implications, this research might have necessary implications for the science of crystal development and deformation as nicely. The Haasen-Alexander-Sumino (HAS) mannequin is an influential theoretical framework used to grasp the habits of dislocations in supplies. However Usami believes that they’ve found dislocations that the Haasen-Alexander-Sumino mannequin missed.

New Insights Into Atom Association

One other shock was to observe quickly after, as when the staff calculated the association of the atoms in these constructions, they discovered unexpectedly giant tensile bond strains alongside the sting of the staircase-like constructions that triggered dislocation technology.

As defined by Usami, “As consultants who’ve been learning this for years, we had been amazed and excited to lastly see proof of the presence of dislocations in these constructions. It means that we will management the formation of dislocation clusters by controlling the route during which the boundary spreads.”

Conclusion and Future Implications

“By extracting and analyzing the nanoscale areas via polycrystalline supplies informatics, which mixes experiment, concept, and AI, we made this clarification of phenomena in complicated polycrystalline supplies doable for the primary time,” Usami continued. “This analysis illuminates the trail in the direction of establishing common pointers for high-performance supplies and is anticipated to contribute to the creation of modern polycrystalline supplies. The potential affect of this analysis extends past photo voltaic cells to the whole lot from ceramics to semiconductors. Polycrystalline supplies are extensively utilized in society, and the improved efficiency of those supplies has the potential to revolutionize society.”

Reference: “Multicrystalline Informatics Utilized to Multicrystalline Silicon for Unraveling the Microscopic Root Reason behind Dislocation Technology” by Kenta Yamakoshi, Yutaka Ohno, Kentaro Kutsukake, Takuto Kojima, Tatsuya Yokoi, Hideto Yoshida, Hiroyuki Tanaka, Xin Liu, Hiroaki Kudo and Noritaka Usami, 2 December 2023, Superior Supplies.

DOI: 10.1002/adma.202308599