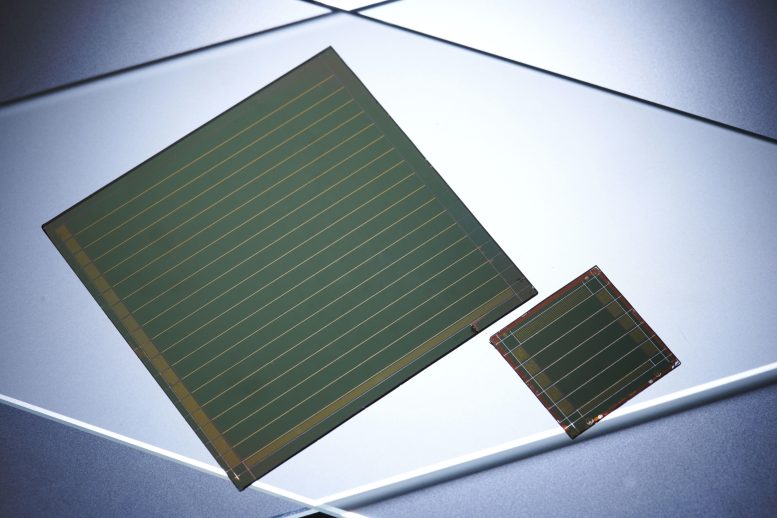

Assisted by AI strategies, researchers are striving to enhance the manufacturing processes for extremely environment friendly perovskite photo voltaic cells. Credit score: Amadeus Bramsiepe, KIT

Synthetic intelligence strategies help scientists in enhancing manufacturing procedures for extremely environment friendly photo voltaic cells, serving as a blueprint for varied different analysis fields.

Perovskite tandem photo voltaic cells symbolize a complicated hybrid expertise, merging a perovskite photo voltaic cell with a conventional photo voltaic cell, typically fabricated from silicon. This progressive method stands on the forefront of photo voltaic expertise, providing a formidable effectivity fee exceeding 33 p.c, considerably surpassing that of ordinary silicon photo voltaic cells.

Furthermore, they use cheap uncooked supplies and are simply manufactured. To attain this degree of effectivity, a particularly skinny high-grade perovskite layer, whose thickness is just a fraction of that of human hair, needs to be produced.

“Manufacturing these high-grade, multi-crystalline skinny layers with none deficiencies or holes utilizing low-cost and scalable strategies is likely one of the largest challenges,” says tenure-track professor Ulrich W. Paetzold who conducts analysis on the Institute of Microstructure Expertise and the Mild Expertise Institute of KIT.

Even below apparently excellent lab situations, there could also be unknown components that trigger variations in semiconductor layer high quality: “This downside ultimately prevents a fast begin of industrial-scale manufacturing of those extremely environment friendly photo voltaic cells, that are wanted so badly for the power turnaround,” explains Paetzold.

AI Finds Hidden Indicators of Efficient Coating

To seek out the components that affect coating, an interdisciplinary crew consisting of the perovskite photo voltaic cell specialists of KIT has joined forces with specialists for Machine Studying and Explainable Synthetic Intelligence (XAI) of Helmholtz Imaging and Helmholtz AI on the DKFZ in Heidelberg.

The researchers developed AI strategies that practice and analyze neural networks utilizing an enormous dataset. This dataset consists of video recordings that present the photoluminescence of the skinny perovskite layers in the course of the manufacturing course of. Photoluminescence refers back to the radiant emission of the semiconductor layers which have been excited by an exterior mild supply.

“Since even specialists couldn’t see something explicit on the skinny layers, the concept was born to coach an AI system for Machine Studying (Deep Studying) to detect hidden indicators of fine or poor coating from the thousands and thousands of information gadgets on the movies,” Lukas Klein and Sebastian Ziegler from Helmholtz Imaging on the DKFZ clarify.

To filter and analyze the broadly scattered indications output by the Deep Studying AI system, the researchers subsequently relied on strategies of Explainable Synthetic Intelligence.

“A Blueprint for Comply with-Up Analysis”

The researchers came upon experimentally that the photoluminescence varies throughout manufacturing and that this phenomenon has an affect on the coating high quality.

“Key to our work was the focused use of XAI strategies to see which components need to be modified to acquire a high-grade photo voltaic cell,” Klein and Ziegler mentioned. This isn’t the standard method. Usually, XAI is just used as a sort of guardrail to keep away from errors when constructing AI fashions.

“This can be a change of paradigm: Gaining extremely related insights in supplies science in such a scientific means is a very new expertise.”

It was certainly the conclusion drawn from the photoluminescence variation that enabled the researchers to take the following step. After the neural networks had been educated accordingly, the AI was in a position to predict whether or not every photo voltaic cell would obtain a low or a excessive degree of effectivity based mostly on which variation of sunshine emission occurred at what level within the manufacturing course of.

“These are extraordinarily thrilling outcomes,” emphasizes Ulrich W. Paetzold. “Because of the mixed use of AI, we’ve a strong clue and know which parameters must be modified within the first place to enhance manufacturing. Now we’re in a position to conduct our experiments in a extra focused means and are now not compelled to look blindfolded for the needle in a haystack. This can be a blueprint for follow-up analysis that additionally applies to many different points of power analysis and supplies science.”

Reference: “Discovering Course of Dynamics for Scalable Perovskite Photo voltaic Cell Manufacturing with Explainable AI” by Lukas Klein, Sebastian Ziegler, Felix Laufer, Charlotte Debus, Markus Götz, Klaus Maier-Hein, Ulrich W. Paetzold, Fabian Isensee and Paul F. Jäger, 30 October 2023, Superior Supplies.

DOI: 10.1002/adma.202307160