By

Progressive high-entropy alloys, crafted by laser-based additive manufacturing, supply unprecedented energy and ductility for industrial purposes. These new supplies, analyzed with superior methods, promise enhanced efficiency in excessive circumstances. Credit score: SciTechDaily.com

Laser-based additive manufacturing produces high-entropy alloys which might be stronger and fewer prone to fracture.

Researchers make a sort of fabric known as sturdy high-entropy alloys (HEAs) by combining a number of elemental metals. HEAs have potential makes use of in purposes involving extreme put on and tear, excessive temperatures, radiation, and excessive stress.

They are often made utilizing 3D printing, often known as additive manufacturing (AM), however this often ends in poor ductility. This implies 3D-printed HEAs are troublesome to form and don’t deform, or stretch, sufficient underneath hundreds to stop fractures.

Scientists have now used laser-based AM to kind HEAs which might be stronger and rather more ductile. They used neutron and X-ray scattering and electron microscopy to raised perceive the mechanisms of those efficiency enhancements.

Potential Industrial Purposes and Power Effectivity

Trade might at some point use stronger and extra simply formed HEAs in manufacturing. To work in these purposes, mild and sophisticated HEA elements want improved sturdiness, reliability, and resistance to fracturing.

This is able to profit shoppers and business, for instance, by enabling the manufacturing of safer and extra fuel-efficient autos, stronger merchandise, and longer-lasting equipment. As well as, laser-based AM, wherein lasers fuse powdered alloys into strong steel shapes, is very power environment friendly. This makes it enticing for producing new kinds of HEAs.

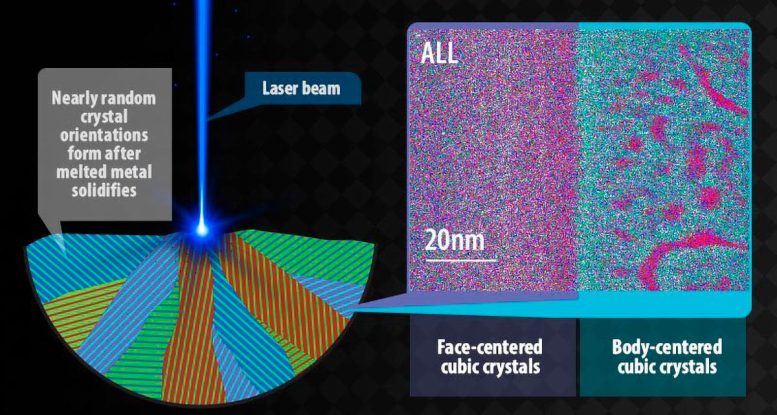

Photos of the 2 crystal constructions (proper) present in a high-entropy alloy (left) made by additive manufacturing. Credit score: College of Massachusetts Amherst

Nano-Lamellae Construction and Mechanical Properties

The laser-based AM course of produced nanometer-thick nano-lamellae (skinny layers of plates) providing excessive energy, whereas the plates’ distinct edges allow a level of slippage (ductility). The plates encompass alternating layers of face-centered cubic (FCC) crystal constructions that common roughly 150 nanometers thick and body-centered cubic (BCC) crystal constructions that common roughly 65 nanometers thick.

The brand new HEAs exhibited excessive yield strengths of about 1.3 gigapascals – exceeding the strongest titanium alloys. These HEAs additionally supply an elongation of about 14%, which is increased than different AM steel alloys given the identical yield energy. Elongation is a measure of how a lot bending a cloth can face up to with out breaking.

Superior Analysis Methods and Services

Neutron knowledge from the Spallation Neutron Source, a Division of Power (DOE) Workplace of Science person facility at Oak Ridge Nationwide Laboratory (ORNL), enabled the researchers to look at the inside mechanical load sharing of the HEA samples whereas underneath pressure.

The researchers used an atom probe instrument on the Center for Nanophase Materials Sciences, additionally a DOE person facility at ORNL, to seize detailed 3D pictures of the compositions and microstructures, consisting of alternating nano-lamellae layers.

The phases of various annealed samples had been studied utilizing X-ray diffraction on the Advanced Photon Source, one other DOE Workplace of Science person facility at Argonne Nationwide Laboratory.

Reference: “Robust but ductile nanolamellar high-entropy alloys by additive manufacturing” by Jie Ren, Yin Zhang, Dexin Zhao, Yan Chen, Shuai Guan, Yanfang Liu, Liang Liu, Siyuan Peng, Fanyue Kong, Jonathan D. Poplawsky, Guanhui Gao, Thomas Voisin, Ke An, Y. Morris Wang, Kelvin Y. Xie, Ting Zhu and Wen Chen, 3 August 2022, Nature.

DOI: 10.1038/s41586-022-04914-8

This analysis was carried out on the Spallation Neutron Supply, the Superior Photon Supply, and Middle for Nanophase Supplies Sciences, all of that are DOE Workplace of Science person amenities. Funding help for this work included the Nationwide Science Basis, the College of Massachusetts Amherst, and the Laboratory Directed Analysis and Growth program at Lawrence Livermore Nationwide Laboratory.