Researchers have developed an ultra-thin lense that may remodel infrared mild into seen mild.

Lenses are probably the most broadly used optical units. Digicam lens or targets, for instance, produce a pointy picture or video by directing mild at a focus.

The pace of evolution made within the discipline of optics in latest many years is exemplified by the transformation of typical cumbersome cameras into as we speak’s compact smartphone cameras.

Even high-performance smartphone cameras nonetheless require a stack of lenses that usually account for the thickest a part of the telephone. This dimension constraint is an inherent function of basic lens design—a thick lens is essential for bending mild to seize a pointy picture on the digicam sensor.

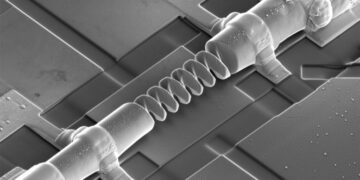

Main strides within the discipline of optics over the previous ten years have sought to beat this limitation and have provide you with an answer within the type of metalenses. They’re flat, carry out in the identical method as regular lenses, and will not be solely 40 instances thinner than a mean human hair but additionally light-weight as they don’t should be made from glass.

A particular metasurface composed of buildings a mere hundred nanometers in width and top (one nanometer is one billionth of a meter) modifies the course of sunshine. Utilizing such nanostructures researchers can radically scale back the scale of a lens and make it extra compact.

When mixed with particular supplies, these nanostructures can be utilized to discover different uncommon properties of sunshine. One instance is nonlinear optics, the place mild is transformed from one colour into one other. A inexperienced laser pen works in accordance with this precept: infrared mild goes by means of a high-quality crystalline materials and generates mild of half the wavelength—on this case inexperienced mild. One well-known materials that produces such results is lithium niobate. That is used within the telecommunications business to create elements that interface electronics with optical fibres.

Rachel Grange, a professor on the Institute for Quantum Electronics at ETH Zurich, conducts analysis into the fabrication of nanostructures with such supplies. She and her staff have developed a brand new course of that permits lithium niobate for use to create metalenses. The examine seems within the journal Advanced Materials.

For her new technique, the physicist combines chemical synthesis with precision nanoengineering.

“The answer containing the precursors for lithium niobate crystals might be stamped whereas nonetheless in a liquid state. It really works in an identical strategy to Gutenberg’s printing press,” co-first writer Ülle-Linda Talts, a doctoral pupil working with Grange, explains. As soon as the fabric is heated to 600°C (1112°F), it takes on crystalline properties that allow the conversion of sunshine as within the case of the inexperienced laser pen.

The method has a number of benefits. Producing lithium niobate nanostructures is tough utilizing typical strategies as it’s exceptionally steady and onerous. In keeping with the researchers, this method is appropriate for mass manufacturing as an inverse mould can be utilized a number of instances, permitting the printing of as many metalenses as wanted. It’s also rather more cost-effective and sooner to manufacture than different lithium niobate miniaturized optical units.

Utilizing this method, the researchers in Grange’s group succeeded in creating the primary lithium niobate metalenses with exactly engineered nanostructures. Whereas functioning as regular mild focusing lenses, these units can concurrently change the wavelength of laser mild. When infrared mild with a wavelength of 800 nanometers is shipped by means of the metalens, seen radiation with a wavelength of 400 nanometers emerges on the opposite aspect and is directed at a delegated level.

This magic of sunshine conversion, as Grange calls it, is just made potential by the particular construction of the ultra-thin metalens and its composition of a fabric that permits the prevalence of what’s often called the nonlinear optical impact. This impact is just not restricted to an outlined laser wavelength, making the method extremely versatile in a broad vary of functions.

Metalenses and comparable hologram-generating nanostructures could possibly be used as security measures to render banknotes and securities counterfeit-proof and to ensure the authenticity of artworks. Their precise buildings are too small to be seen utilizing seen mild, whereas their nonlinear materials properties permit extremely dependable authentication.

Researchers also can use easy digicam detectors to transform and steer the emission of laser mild to make infrared mild—in sensors, for instance—seen. Or for decreasing the gear wanted for deep-UV mild patterning in state-of-the-art electronics fabrication.

The sphere of such ultra-thin optical parts—often called metasurfaces—is a comparatively younger department of analysis on the interface between physics, supplies science and chemistry.

“We’ve got solely scratched the floor up to now and are very excited to see how a lot of an affect the sort of new cost-effective know-how could have sooner or later,” emphasizes Grange.

The examine was funded partly by an SNFS Consolidator Grant to Rachel Grange.

Supply: ETH Zurich