A brand new examine reveals how you can rewire micro organism to supply extra vitamin K₂ for dietary supplements and fortified meals.

Engineering microbes to overproduce nutritional vitamins supplies a greener and more cost effective different to chemical synthesis or extraction from crops and animals.

Nevertheless, bacterial cells sometimes restrict their manufacturing to self-sustaining ranges. By dissecting the management system for the vitamin K₂ precursor, the researchers have recognized how substrate availability and genetic structure impose a manufacturing ceiling in addition to how these limits might be lifted.

“Vitamin-producing microbes may rework vitamin and drugs, however we should first decode their inherent checks and balances,” says Caroline Ajo‑Franklin, co-corresponding writer of the examine, a professor of biosciences, director of the Rice Artificial Biology Institute, and a Most cancers Prevention and Analysis Institute of Texas (CPRIT) Scholar.

“Our work exhibits how L. lactis [Lactococcus lactis] finely tunes its inside provide of the K₂ precursor, permitting us to rewire it with precision.”

The examine, revealed within the mBio journal, focuses on the unstable intermediate compound that channels all types of vitamin K₂.

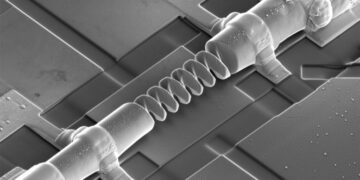

The researchers employed a three-pronged method: biosensing, genetic engineering, and mathematical modeling. As a result of the precursor is tough to detect, the group constructed a customized biosensor in a distinct bacterium. This sensor is hundreds of occasions extra delicate than typical strategies and requires minimal lab gear.

Subsequent, the researchers used genetic instruments to change the degrees of enzymes within the biosynthetic pathway. By measuring precursor output underneath totally different situations, they fed the outcomes right into a mathematical mannequin of the pathway. Initially, the mannequin assumed a limiteless precursor provide, however predictions didn’t align with laboratory outcomes.

“As soon as we allowed for depletion of the beginning substrate, the mannequin output matched our experimental knowledge,” says Oleg Igoshin, co-corresponding writer and professor of bioengineering and biosciences.

“It grew to become clear that cells hit a pure manufacturing ceiling when the substrate runs low.”

Information and modeling indicated that L. lactis maintains precursor ranges at an optimum steadiness, excessive sufficient for its personal wants however low sufficient to keep away from toxicity. Merely overexpressing pathway enzymes didn’t improve output past the brink as a result of precursor supplies grew to become restricted, very like making an attempt to bake extra cookies with additional baking sheets however with out sufficient flour.

The order of enzyme-encoding genes on DNA additionally influenced precursor ranges: Rearranging these genes altered how a lot intermediate the cell produced. This implies a further layer of evolutionary regulation that has not been nicely understood.

“By tuning substrate provide, enzyme expression and gene order concurrently, we are able to push manufacturing above the pure ceiling,” says Siliang Li, the primary writer of the examine and a former graduate pupil who’s now a postdoctoral fellow at Rice.

This perception opens the door to engineering L. lactis or different food-grade micro organism to supply extra vitamin K₂ in fermentation processes and even in probiotic formulations.

“Enhanced manufacturing may cut back the necessity for feedstocks and lab area, finally reducing prices and bringing fortified meals and dietary supplements nearer to actuality,” says Jiangguo Zhang, co-first writer and a Rice graduate pupil.

This examine was supported by CPRIT and the Nationwide Science Basis and facilitated by the Rice Artificial Biology Institute.

Supply: Rice University