Columbia researchers are utilizing DNA—the organic instruction guide of life—because the core constructing block for setting up intricate, useful nanomaterials.

Taking inspiration from nature’s personal bottom-up design, the staff has developed a way that applications DNA to assemble into voxel-shaped scaffolds that can organize other nanoscale components. This allows them to fabricate complex 3D structures such as light-reflecting crystals, miniaturized electronics, and brain-like circuits.

From Skyscrapers to Nanoscaffolds

When the Empire State Building was constructed, its 102 stories rose over Manhattan one section at a time. Piece by piece, it became the tallest structure in the world for four decades. At Columbia University, however, Oleg Gang and his chemical engineering team are working on something far smaller. Instead of towering skyscrapers, they’re developing microscopic devices made from self-organizing components at the nanoscale.

“We can build now the complexly prescribed 3D organizations from self-assembled nanocomponents, a kind of nanoscale version of the Empire State Building,” said Gang, professor of chemical engineering and of applied physics and materials science at Columbia Engineering and leader of the Center for Functional Nanomaterials’ Soft and Bio Nanomaterials Group at Brookhaven National Laboratory.

A Versatile Platform for Nanoscale Innovation

“The capabilities to manufacture 3D nanoscale materials by design are critical for many emerging applications, ranging from light manipulation to neuromorphic computing, and from catalytic materials to biomolecular scaffolds and reactors,” said Gang.

In two recent papers, one published in Nature Materials and the other in ACS Nano, Gang and his team present a new approach to building complex 3D nanoscale structures using self-assembly. Their method can be applied across multiple fields and includes a design algorithm that others can use to replicate the process.

The foundation of their work? It all starts with one of biology’s most essential molecules: DNA.

One Pot Stop for New Materials

When it comes to small-scale fabrication of microelectronics, conventional approaches are based on top-down strategies. One common approach is photolithography, which uses powerful light and intricate stencils to etch circuits. But mainstream lithographic techniques struggle with complex, three-dimensional structures, while additive manufacturing, better known as 3D printing, cannot yet fabricate features at the nanoscale. In terms of workflow, both methods fabricate each feature one by one, in serial. This is an intrinsically slow process for building 3D objects.

Taking his cues from biological systems, Gang builds 3D materials and devices from the bottom up via self-assembly processes directed by DNA. He has been refining his method through collaborations with other scientists to build, for example, extremely small electronics that they need for their work.

DNA-Directed Light Sensors and Other Innovations

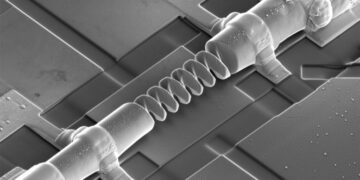

Two months ago, he and his former student, Aaron Michelson, now a staff scientist at Brookhaven National Laboratory’s Center for Functional Nanomaterials, delivered a prototype for collaborators at the University of Minnesota interested in creating 3D light sensors integrated onto microchips. They built the sensors by growing DNA scaffolds on a chip and then coating them with light-sensitive material.

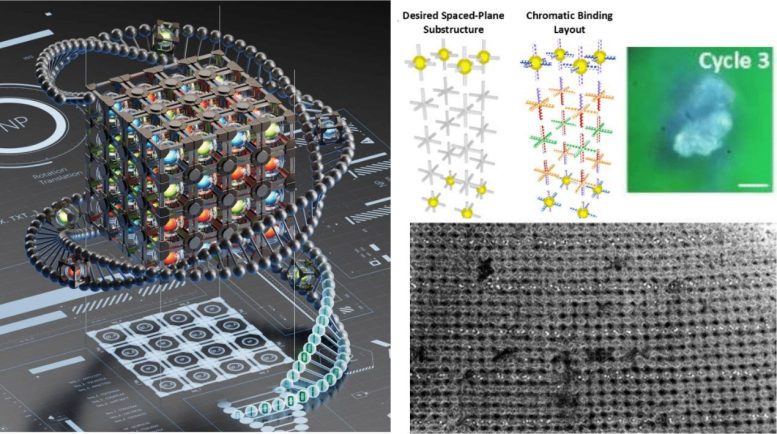

That device was just the first of many. In their latest paper in Nature Materials, Gang and his team establish an inverse design strategy for creating the desired 3D structures from a set of nanoscale DNA components and nanoparticles. The study presents four additional applications of their “DNA origami” approach to material design: a crystal-like structure comprised of one-dimensional strings and two-dimensional layers; a mimic of the materials found commonly in solar panels; another crystal that spins in a helical swirl; and, for collaborator Nanfang Yu, professor of applied physics at Columbia Engineering, a structure that will reflect light in particular ways for his goal of one day creating an optical computer.

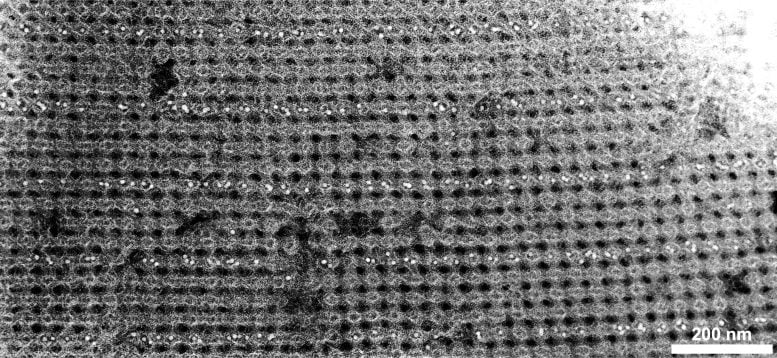

Parallel Assembly in Water Wells

Using advanced characterization techniques, such as synchrotron-based x-ray scattering and electron microscopy methods, at Columbia and Brookhaven National Laboratories, the team confirmed that the resulting structures matched their designs and revealed the designed considerations for improving structure fidelity. Each of these unique structures assembled itself in water wells in Gang’s lab. This type of material formation is parallel in its nature since the components come together during the assembly process, meaning significant time- and cost-savings for 3D fabrication compared with traditional methods. The fabrication process is also environmentally friendly as the assembly occurs in water.

This assembly methodology, coupled with liquid robotics automatization on which I am working now at BNL, opens new possibilities for establishing 3D nano-manufacturing for a broad range of applications,” said Brian Minevich, co-first author on the paper, who was a PhD student in Gang’s lab and is now a postdoctoral fellow at BNL.

“This is a platform that is applicable to many materials with many different properties: biological, optical, electrical, magnetic,” said Gang. The end result simply depends on the design.

DNA Design, Made Easy

DNA folds predictably, as the four nucleic acids that make it up can only pair in particular combinations. But when the desired structure contains millions, if not billions of pieces, how do you come up with the correct starting sequence?

Gang and his colleagues solve this challenge with an inverse structural design approach. “If we know the big structure with the function that we want to create, we can dissect that into smaller components to create our building blocks with structural, binding, and functional attributes required to form the desired structure,” said Gang.

The building blocks are strands of DNA that fold into a mechanically robust eight-sided octahedral shape, which Gang refers to as a voxel, with connectors at each corner that link each voxel together. Many voxels can be designed to link up into a particular repetitive 3D motif using DNA encoding, similar to how jigsaw puzzle pieces form a complex picture. The repetitive motifs, in turn, are also assembled in parallel to create the targeted hierarchically organized structure. Collaborator Sanat Kumar, the Michael Bykhovsky and Charo Gonzalez-Bykhovsky Professor of Chemical Engineering at Columbia, provided a computational verification of Gang’s inverse design approach.

To enable the inverse design strategy, the researchers must figure out how to design these DNA-based nanoscale “jigsaw puzzle pieces” with the minimal number needed to form the desired structure. “You can think of it like compressing a file. We want to minimize the amount of information for the DNA self-assembly to be most efficient,” said first author Jason Kahn, a staff scientist at BNL and previously a postdoc at Gang’s group. Dubbed Mapping Of Structurally Encoded aSsembly, or MOSES, this algorithm is like nano-scale CAD software, Gang adds. “It will tell you what DNA voxel to use to make a particular, arbitrarily defined 3D hierarchically ordered lattice.”

Embedding Functionality Inside Nanostructures

From there, you can add diverse types of nano-“cargo” inside the DNA voxels that will imbue the final structure with particular properties. For example, gold nanoparticles were embedded to give unique optical properties, as demonstrated in Yu’s experiments. But, as shown previously, both inorganic and bio-derived nanocomponents can be integrated into these DNA scaffolds. Once the device was assembled, the team also “mineralized” it. They coated scaffolds with silica and then exposed them to heat to decompose the DNA, effectively converting the original organic scaffolding into a highly robust inorganic form.

Gang continues to collaborate with Kumar and Yu to uncover design principles that will allow for the engineering and assembly of complex structures, hoping to realize even more complicated designs, including a 3D circuit intended to mimic the complex connectivity of the human brain.

Massively Parallel 3D Printing at the Nanoscale

“We are well on our way to establishing a bottom-up 3D nanomanufacturing platform. We see this as a ‘next-generation 3D printing’ at the nanoscale, but now the power of DNA-based self-assembly allows us to establish massively parallel fabrication,” said Gang.

References:

“Encoding hierarchical 3D architecture through inverse design of programmable bonds” by Jason S. Kahn, Brian Minevich, Aaron Michelson, Hamed Emamy, Jiahao Wu, Huajian Ji, Alexia Yun, Kim Kisslinger, Shuting Xiang, Nanfang Yu, Sanat K. Kumar and Oleg Gang, 9 July 2025, Nature Materials.

DOI: 10.1038/s41563-025-02263-1

“Arbitrary Design of DNA-Programmable 3D Crystals through Symmetry Mapping” by Jason S. Kahn, Daniel C. Redeker, Aaron Michelson, Alexei Tkachenko, Sarah Hong, Brian Minevich and Oleg Gang, 11 April 2025, ACS Nano.

DOI: 10.1021/acsnano.4c17408

Never miss a breakthrough: Join the SciTechDaily newsletter.