Researchers have developed a way to interrupt down PET, one of many world’s most generally used plastics, for sustainable recycling utilizing mechanical forces as an alternative of warmth or harsh chemical substances.

Whereas plastics assist allow trendy requirements of residing, their accumulation in landfills and the general setting continues to develop as a worldwide concern.

Polyethylene terephthalate (PET) is likely one of the world’s most generally used plastics, with tens of thousands and thousands of tons produced yearly within the manufacturing of bottles, meals packaging, and clothes fibers. The sturdiness that makes PET so helpful additionally implies that it’s harder to recycle effectively.

The brand new findings within the journal Chem present how a “mechanochemical” technique—chemical reactions pushed by mechanical forces comparable to collisions—can quickly convert PET again into its fundamental constructing blocks, opening a path towards faster, cleaner recycling.

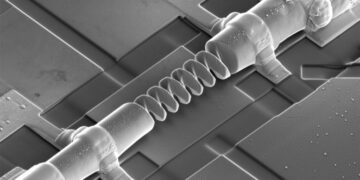

Led by postdoctoral researcher Kinga Gołąbek and Professor Carsten Sievers of Georgia Tech’s College of Chemical and Biomolecular Engineering, the analysis crew hit stable items of PET with metallic balls with the identical drive they might expertise in a machine referred to as a ball mill. This may make the PET react with different stable chemical substances comparable to sodium hydroxide (NaOH), producing sufficient power to interrupt the plastic’s chemical bonds at room temperature, with out the necessity for hazardous solvents.

“We’re displaying that mechanical impacts may also help decompose plastics into their unique molecules in a controllable and environment friendly means,” Sievers says. “This might rework the recycling of plastics right into a extra sustainable course of.”

In demonstrating the method, the researchers used managed single-impact experiments together with superior pc simulations to map how power from collisions distributes throughout the plastic and triggers chemical and structural transformations.

These experiments confirmed adjustments in construction and chemistry of PET in tiny zones that have totally different pressures and warmth. By mapping these transformations, the crew gained new insights into how mechanical power can set off speedy, environment friendly chemical reactions.

“This understanding might assist engineers design industrial-scale recycling programs which are quicker, cleaner, and extra energy-efficient,” Gołąbek says.

Every collision created a tiny crater, with the middle absorbing essentially the most power. On this zone, the plastic stretched, cracked, and even softened barely, creating perfect situations for chemical reactions with sodium hydroxide.

Excessive-resolution imaging and spectroscopy revealed that the usually ordered polymer chains turned disordered within the crater heart, whereas some chains broke into smaller fragments, rising the floor space uncovered to the reactant. Even with out sodium hydroxide, mechanical impression alone precipitated minor chain breaking, displaying that mechanical drive itself can set off chemical change.

The examine additionally confirmed the significance of the quantity of power delivered by every impression. Low-energy collisions solely barely disturb PET, however stronger impacts trigger cracks and plastic deformation, exposing new surfaces that may react with sodium hydroxide for speedy chemical breakdown.

“Understanding this power threshold permits engineers to optimize mechanochemical recycling, maximizing effectivity whereas minimizing pointless power use,” Sievers defined.

These findings level towards a future the place plastics will be absolutely recycled again into their unique constructing blocks, reasonably than being downcycled or discarded. By harnessing mechanical power as an alternative of warmth or harsh chemical substances, recycling might change into quicker, cleaner, and extra energy-efficient.

“This strategy might assist shut the loop on plastic waste,” Sievers says. “We might think about recycling programs the place on a regular basis plastics are processed mechanochemically, giving waste new life repeatedly and lowering environmental impression.”

The crew now plans to check real-world waste streams and discover whether or not comparable strategies can work for different difficult-to-recycle plastics, bringing mechanochemical recycling nearer to industrial use.

“With thousands and thousands of tons of PET produced yearly, enhancing recycling effectivity might considerably reduce plastic pollution and assist shield ecosystems worldwide,” Gołąbek says.

Supply: Georgia Tech