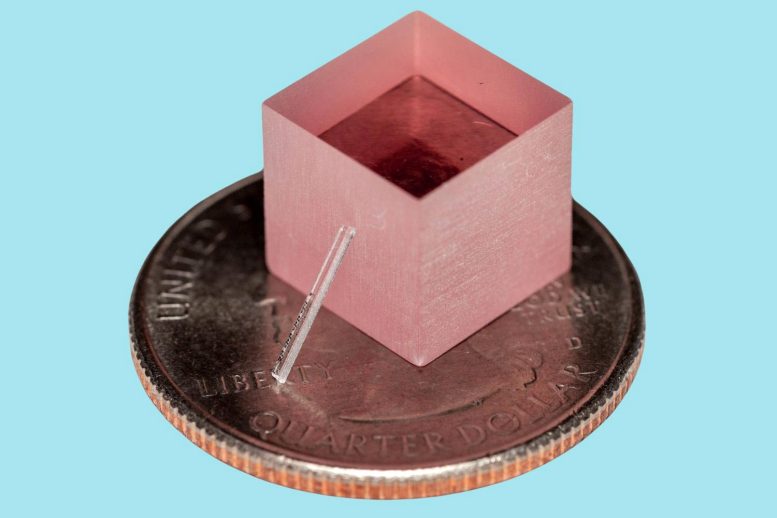

The brand new laser leans in opposition to a block of titanium-sapphire. For scale, each sit atop 1 / 4. Credit score: Yang et al., Nature

In a single leap from tabletop to the microscale, engineers at Stanford College have produced the world’s first sensible titanium-sapphire laser on a chip.

Researchers have developed a chip-scale Titanium-sapphire laser that’s considerably smaller and cheaper than conventional fashions, making it accessible for broader purposes in quantum optics, neuroscience, and different fields. This new know-how is predicted to allow labs to have a whole bunch of those highly effective lasers on a single chip, fueled by a easy inexperienced laser pointer.

As lasers go, these manufactured from Titanium-sapphire (Ti:sapphire) are thought-about to have “unmatched” efficiency. They’re indispensable in lots of fields, together with cutting-edge quantum optics, spectroscopy, and neuroscience. However that efficiency comes at a steep value. Ti:sapphire lasers are huge, on the order of cubic toes in quantity. They’re costly, costing a whole bunch of hundreds of {dollars} every. They usually require different high-powered lasers, themselves costing $30,000 every, to provide them with sufficient vitality to operate.

Breakthrough in Laser Expertise

In consequence, Ti:sapphire lasers have by no means achieved the broad, real-world adoption they deserve – till now. In a dramatic leap ahead in scale, effectivity, and price, researchers at Stanford College have constructed a Ti:sapphire laser on a chip. The prototype is 4 orders of magnitude smaller (10,000x) and three orders inexpensive (1,000x) than any Ti:sapphire laser ever produced.

Revolutionary Miniaturization and Price Discount

“This can be a full departure from the previous mannequin,” stated Jelena Vučković, the Jensen Huang Professor in International Management, a professor {of electrical} engineering, and senior creator of the paper introducing the chip-scale Ti:sapphire laser printed within the journal Nature. “As a substitute of 1 giant and costly laser, any lab would possibly quickly have a whole bunch of those precious lasers on a single chip. And you’ll gas all of it with a inexperienced laser pointer.”

“Once you leap from tabletop measurement and make one thing producible on a chip at such a low value, it places these highly effective lasers in attain for lots of various essential purposes,” stated Joshua Yang, a doctoral candidate in Vučković’s lab and co-first creator of the examine together with Vučković’s Nanoscale and Quantum Photonics Lab colleagues, analysis engineer Kasper Van Gasse and postdoctoral scholar Daniil M. Lukin.

Technical Benefits and Mass Manufacturing Potential

In technical phrases, Ti:sapphire lasers are so precious as a result of they’ve the most important “acquire bandwidth” of any laser crystal, defined Yang. In easy phrases, acquire bandwidth interprets to the broader vary of colours the laser can produce in comparison with different lasers. It’s additionally ultrafast, Yang stated. Pulses of sunshine difficulty forth each quadrillionth of a second.

However Ti:sapphire lasers are additionally laborious to return by. Even Vučković’s lab, which does cutting-edge quantum optics experiments, solely has a couple of of those prized lasers to share. The brand new Ti:sapphire laser matches on a chip that’s measured in sq. millimeters. If the researchers can mass-produce them on wafers, doubtlessly hundreds, maybe tens-of-thousands of Ti:sapphire lasers could possibly be squeezed on a disc that matches within the palm of a human hand.

“A chip is gentle. It’s transportable. It’s cheap and it’s environment friendly. There aren’t any shifting components. And it may be mass-produced,” Yang stated. “What’s to not like? This democratizes Ti:sapphire lasers.”

Improvements in Manufacturing

To vogue the brand new laser, the researchers started with a bulk layer of Titanium-sapphire on a platform of silicon dioxide (SiO2), all using atop true sapphire crystal. They then grind, etch, and polish the Ti:sapphire to a particularly skinny layer, only a few hundred nanometers thick. Into that skinny layer, they then sample a swirling vortex of tiny ridges. These ridges are like fiber-optic cables, guiding the sunshine round and round, constructing in depth. The truth is, the sample is called a waveguide.

“Mathematically talking, depth is energy divided by space. So, in case you keep the identical energy because the large-scale laser, however cut back the realm wherein it’s concentrated, the depth goes by the roof,” Yang says. “The small scale of our laser really helps us make it extra environment friendly.”

The remaining piece of the puzzle is a microscale heater that warms the sunshine touring by the waveguides, permitting the Vučković crew to alter the wavelength of the emitted gentle to tune the colour of the sunshine wherever between 700 and 1,000 nanometers – within the purple to infrared.

Purposes and Future Prospects

Vučković, Yang, and colleagues are most excited concerning the vary of fields that such a laser would possibly impression. In quantum physics, the brand new laser gives a reasonable and sensible answer that would dramatically scale down state-of-the-art quantum computer systems. In neuroscience, the researchers can foresee fast software in optogenetics, a subject that permits scientists to regulate neurons with gentle guided contained in the mind by comparatively cumbersome optical fiber. Small-scale lasers, they are saying, may be built-in into extra compact probes opening up new experimental avenues. In ophthalmology, it’d discover new use with Nobel Prize-winning chirped pulse amplification in laser surgical procedure or supply inexpensive, extra compact optical coherence tomography applied sciences used to evaluate retinal well being.

Subsequent up, the crew is engaged on perfecting their chip-scale Ti:sapphire laser and on methods to mass-produce them, hundreds at a time, on wafers. Yang will earn his doctorate this summer season based mostly on this analysis and is working to carry the know-how to market.

“We might put hundreds of lasers on a single 4-inch wafer,” Yang says. “That’s when the fee per laser begins to change into virtually zero. That’s fairly thrilling.”

Reference: “Titanium:sapphire-on-insulator built-in lasers and amplifiers” by Joshua Yang, Kasper Van Gasse, Daniil M. Lukin, Melissa A. Guidry, Geun Ho Ahn, Alexander D. White and Jelena Vučković, 26 June 2024, Nature.

DOI: 10.1038/s41586-024-07457-2

Contributing authors embrace postdoctoral scholar Melissa A. Guidry and doctoral candidates Geun Ho Ahn and Alexander D. White. Vučković can also be a member of Stanford Bio-X, Stanford PULSE Institute, and the Wu Tsai Neurosciences Institute.

Funding for this analysis courtesy of the Institute of Engineering and Expertise A.F. Harvey Prize, the Vannevar Bush College Fellowship from the U.S. Division of Protection, the Protection Superior Analysis Initiatives Company (DARPA), and the Air Drive Workplace of Scientific Analysis (AFOSR). A part of this work was carried out on the Stanford Nano Shared Services (SNSF)/Stanford Nanofabrication Facility (SNF), supported by the Nationwide Science Basis.