Hydrogen might be a green fuel of the future, however at current it’s primarily made out of fossil fuels in a course of that generates lots of CO2. A brand new approach, nevertheless, generates hydrogen gasoline from plastic waste with no direct carbon emissions, whereas creating useful graphene as a byproduct.

Batteries are presently the main method to decarbonizing transportation, however utilizing hydrogen as a gas nonetheless has appreciable benefits. It has considerably larger vitality density, which might give hydrogen-powered automobiles better vary, and refueling with hydrogen is far sooner than recharging a battery. It’s additionally a promising gas for heavy industries like steelmaking that may’t be simply electrified and might be helpful for long-term vitality storage.

Hydrogen’s inexperienced credentials rely closely on the way it’s produced although. Utilizing electrical energy to separate water into hydrogen and oxygen will be sustainable if powered by renewable vitality. However the course of is presently very costly, and most hydrogen immediately is as an alternative made by reacting methane from fossil fuels with steam, producing appreciable quantities of CO2 as a byproduct.

A promising new course of developed by researchers at Rice College generates hydrogen from plastic waste with out straight emitting CO2. In fact, it too would have to be powered by renewable vitality. However along with yielding hydrogen, the method additionally produces commercial-grade graphene as a byproduct, which will be bought to pay for the hydrogen manufacturing.

“We transformed waste plastics—together with combined waste plastics that don’t need to be sorted by kind or washed—into high-yield hydrogen gasoline and high-value graphene,” Kevin Wyss, who led the analysis whereas doing his PhD at Rice, said in a press release. “If the produced graphene is bought at solely 5 p.c of present market worth—a 95 p.c off sale—clear hydrogen might be produced totally free.”

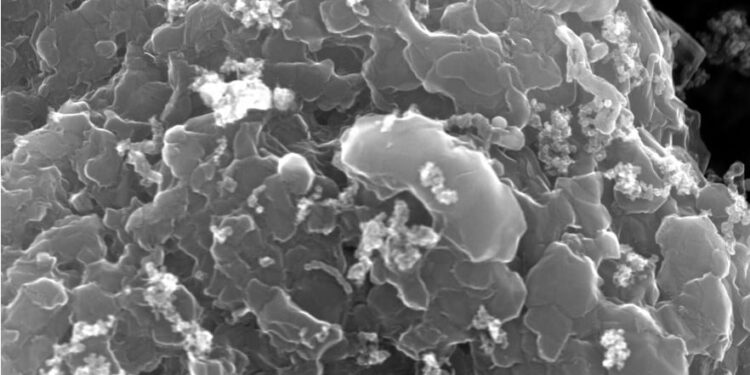

The brand new course of depends on a method generally known as flash joule heating, which was developed within the lab of Rice professor James Tour. It entails grinding plastic into confetti-size items, mixing it with a conductive materials, putting it in a tube, after which passing a really excessive voltage by means of it. This heats the combination to round 5,000 levels Fahrenheit in simply 4 seconds, inflicting the carbon atoms within the plastic to fuse collectively into graphene and releasing a mixture of unstable gases.

The lab initially targeted on utilizing the approach to show waste plastic into graphene, and Tour based a startup known as Common Matter to commercialize the method. However after analyzing the composition of the vapor byproducts, the group realized they contained a major quantity of hydrogen gasoline with a purity as excessive as 94 p.c. The outcomes have been revealed in a latest paper in Advanced Materials.

By locking up all of the plastic’s carbon in graphene, the method produces hydrogen with out releasing any CO2. And the economics are very engaging in comparison with different strategies of manufacturing inexperienced hydrogen—the feedstock is a waste product, and promoting the graphene for even a fraction of the present market worth primarily means the hydrogen is being produced totally free.

Getting the method to work at an industrial scale will inevitably be difficult, Upul Wijayantha at Cranfield College within the UK, told New Scientist. “We don’t know, past the lab scale, what sort of challenges they’ll encounter once they deal with a large scale of plastics, gasoline mixtures and byproducts, like graphene,” he says.

Nonetheless, Tour is optimistic that the method might be commercialized comparatively shortly. “You may have a smaller-scale deployment for producing hydrogen actually inside 5 years,” he advised New Scientist. “You may have a large-scale deployment inside 10.”

If he’s proper, the brand new approach might kill two birds with one stone—serving to sort out plastic waste and producing inexperienced fuels .

Picture Credit score: Layered stacks of flash graphene formed from plastic waste. (Kevin Wyss/Tour lab)