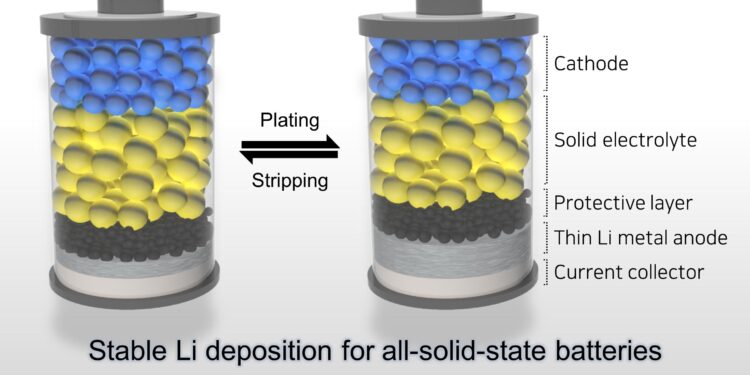

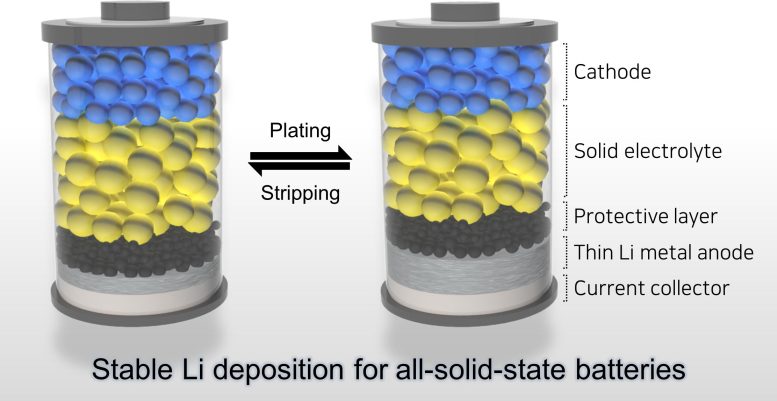

Diagram depicting the stabilization of a lithium metallic anode-based all-solid-state battery by means of the underside electrodeposition mechanism. Credit score: POSTECH

Breakthrough in all-solid-state battery expertise with a novel electrodeposition technique will increase effectivity and lifespan.

A analysis group, consisting of Professor Soojin Park from the Division of Chemistry, PhD candidate Sangyeop Lee from the Division of Superior Supplies Science, and Dr. Sungjin Cho and Grasp’s pupil Hyunbeen Choi from the Division of Chemistry at Pohang College of Science and Know-how (POSTECH), and Dr. Jin Hong Kim and Dr. Hongyeul Bae from the POSCO N.EX.T Hub, has just lately enhanced the efficiency and sturdiness of all-solid-state batteries efficiently. This breakthrough was made attainable by means of the implementation of a novel strategy referred to as backside electrodeposition.[1] Their analysis has been printed within the worldwide journal Small.

Addressing the Challenges of Battery Security

Utilized in numerous purposes akin to electrical automobiles and vitality storage programs, secondary batteries typically depend on liquid electrolytes. Nevertheless, the flammability of liquid electrolytes poses a threat of fires. This prompts ongoing analysis efforts to discover using stable electrolytes and the metallic lithium (Li) in all-solid-state batteries, providing a safer possibility.

Within the operation of all-solid-state batteries, lithium is plated onto an anode, and the motion of electrons is harnessed to generate electrical energy. Through the charging and discharging course of, lithium metallic undergoes a cycle of shedding electrons, remodeling into an ion, regaining electrons, and being electrodeposited again into its metallic kind. Nevertheless, indiscriminate electrodeposition of lithium can rapidly deplete the out there lithium, resulting in a big discount within the battery’s efficiency and sturdiness.

Improvements in Anode Safety

To deal with this situation, the analysis group collaborated with the POSCO N.EX.T Hub to develop an anode safety layer composed of a purposeful binder (PVA-g-PAA)[2] for all-solid-state batteries. This layer reveals distinctive lithium switch properties, stopping random electrodeposition and selling a means of ‘backside electrodeposition.’ This ensures that lithium is uniformly deposited from the underside of the anode floor.

Utilizing scanning electron microscope (SEM), the analysis group performed an evaluation that confirmed the steady electrodeposition and detachment[3] of lithium ions. This considerably diminished pointless lithium consumption. All-solid-state batteries developed by the group additionally demonstrated steady electrochemical efficiency over prolonged durations even with lithium metallic as skinny as 10 micrometers (μm) or much less.

Professor Soojin Park who led the analysis expressed his dedication by saying, “We’ve devised an everlasting all-solid-state battery system by means of a novel electrodeposition technique.” He added, “With additional analysis, we goal to offer more practical methods to reinforce battery life and enhance vitality density.” Constructing on the collaborative findings, POSCO Holdings plans to maneuver in direction of the commercialization of lithium metallic anodes, a core materials for the subsequent technology of secondary batteries.

Notes

- Electrodeposition

The tactic of depositing a metallic onto an electrode submerged in an electrolyte by passing an electrical present by means of the electrolyte - PVA-g-PAA

Poly (vinyl alcohol)-grafting-poly (acrylic acid) - Detach

To interrupt away or separate, a phenomenon the place lithium metallic loses electrons and transforms into lithium ions

Reference: “Backside Deposition Allows Steady All-Strong-State Batteries with Ultrathin Lithium Metallic Anode” by Sangyeop Lee, Sungjin Cho, Hyunbeen Choi, Sungho Kim, Insu Jeong, Yubin Lee, Taesun Choi, Hongyeul Bae, Jin Hong Kim and Soojin Park, 15 February 2024, Small.

DOI: 10.1002/smll.202311652

The analysis was performed with help from the POSCO Holdings, the Ministry of Commerce, Business and Power, and the Korea Planning & Analysis Institute of Industrial Know-how (KEIT).