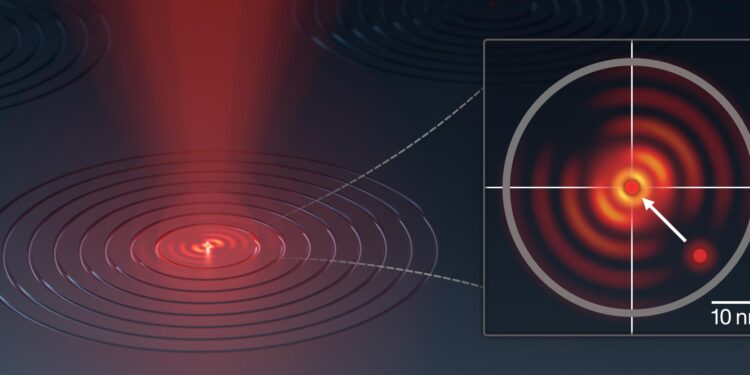

Correct alignment of quantum dots with photonic parts is important for extracting the radiation emitted by the dots. On this illustration, a quantum dot centered within the optical “hotspot” of a round grating (middle dot within the inset) emits extra gentle than a dot that’s misaligned (off-center dot within the inset). Credit score: S. Kelley/NIST

Traceable microscopy might enhance the reliability of quantum data applied sciences, organic imaging, and extra.

Units that seize the sensible gentle from hundreds of thousands of quantum dots, together with chip-scale lasers and optical amplifiers, have made the transition from laboratory experiments to industrial merchandise. However newer kinds of quantum-dot units have been slower to return to market as a result of they require terribly correct alignment between particular person dots and the miniature optics that extract and information the emitted radiation.

Breakthrough in Quantum Dot Alignment

Researchers on the Nationwide Institute of Requirements and Expertise (NIST) and their colleagues have now developed requirements and calibrations for optical microscopes that enable quantum dots to be aligned with the middle of a photonic element to inside an error of 10 to twenty nanometers (about one-thousandth the thickness of a sheet of paper). Such alignment is important for chip-scale units that make use of the radiation emitted by quantum dots to retailer and transmit quantum data.

Enhancing Quantum Gadget Efficiency

For the primary time, the NIST researchers achieved this stage of accuracy throughout your complete picture from an optical microscope, enabling them to right the positions of many particular person quantum dots. A mannequin developed by the researchers predicts that if microscopes are calibrated utilizing the brand new requirements, then the variety of high-performance units might enhance by as a lot as a hundred-fold.

That new potential might allow quantum data applied sciences which can be slowly rising from analysis laboratories to be extra reliably studied and effectively developed into industrial merchandise.

Calibration Challenges and Options

In growing their technique, Craig Copeland, Samuel Stavis, and their collaborators, together with colleagues from the Joint Quantum Institute (JQI), a analysis partnership between NIST and the College of Maryland, created requirements and calibrations that have been traceable to the Worldwide System of Items (SI) for optical microscopes used to information the alignment of quantum dots.

“The seemingly easy thought of discovering a quantum dot and putting a photonic element on it seems to be a difficult measurement drawback,” Copeland mentioned.

Addressing Microscopic Measurement Errors

In a typical measurement, errors start to build up as researchers use an optical microscope to seek out the situation of particular person quantum dots, which reside at random places on the floor of a semiconductor materials. If researchers ignore the shrinkage of semiconductor supplies on the ultracold temperatures at which quantum dots function, the errors develop bigger. Additional complicating issues, these measurement errors are compounded by inaccuracies within the fabrication course of that researchers use to make their calibration requirements, which additionally impacts the position of the photonic parts.

NIST’s Methodological Improvements

The NIST technique, which the researchers described in an article posted on-line in Optica Quantum on March 18, identifies and corrects such errors, which have been beforehand neglected.

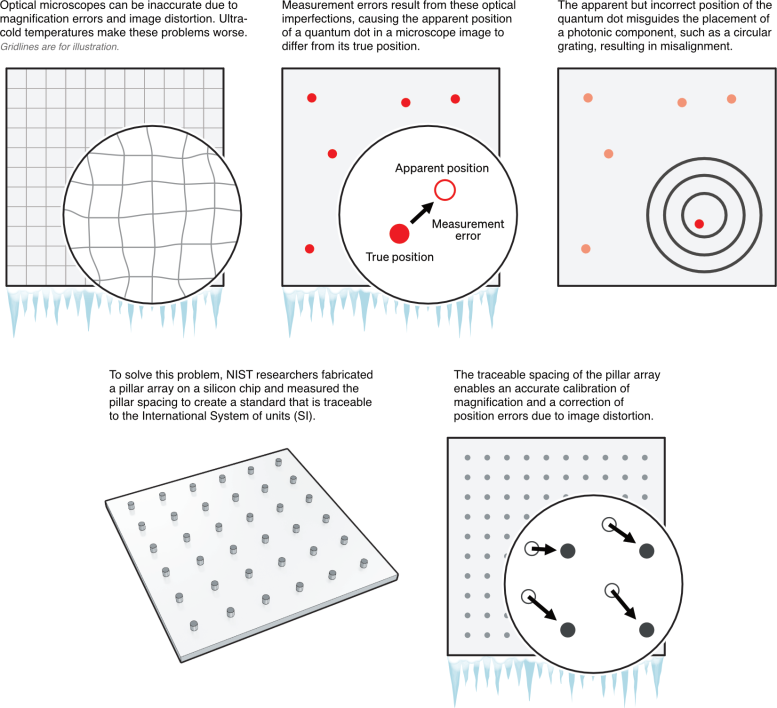

Illustration displaying how traceable calibration of an optical microscope can right for instrument imperfections that may in any other case end in misalignment of quantum dots with photonic parts. Credit score: S. Kelley/NIST

The NIST crew created two kinds of traceable requirements to calibrate optical microscopes—first at room temperature to investigate the fabrication course of, after which at cryogenic temperatures to measure the situation of quantum dots. Constructing on their previous work, the room-temperature commonplace consisted of an array of nanoscale holes spaced a set distance aside in a metallic movie.

The researchers then measured the precise positions of the holes with an atomic power microscope, making certain that the positions have been traceable to the SI. By evaluating the obvious positions of the holes as seen by the optical microscope with the precise positions, the researchers assessed errors from magnification calibration and picture distortion of the optical microscope. The calibrated optical microscope might then be used to quickly measure different requirements that the researchers fabricated, enabling a statistical evaluation of the accuracy and variability of the method.

“Good statistics are important to each hyperlink in a traceability chain,” mentioned NIST researcher Adam Pintar, a co-author of the article.

Extending their technique to low temperatures, the analysis crew calibrated an ultracold optical microscope for imaging quantum dots. To carry out this calibration, the crew created a brand new microscopy commonplace—an array of pillars fabricated on a silicon wafer. The scientists labored with silicon as a result of the shrinkage of the fabric at low temperatures has been precisely measured.

Overcoming Optical Distortions at Low Temperatures

The researchers found a number of pitfalls in calibrating the magnification of cryogenic optical microscopes, which are likely to have worse picture distortion than microscopes working at room temperature. These optical imperfections bend the pictures of straight traces into gnarled curves that the calibration successfully straightens out. If uncorrected, the picture distortion causes massive errors in figuring out the place of quantum dots and in aligning the dots inside targets, waveguides, or different light-controlling units.

“These errors have possible prevented researchers from fabricating units that carry out as predicted,” mentioned NIST researcher Marcelo Davanco, a co-author of the article.

Quantum Dot Gadget Enchancment and Future Functions

The researchers developed an in depth mannequin of the measurement and fabrication errors in integrating quantum dots with chip-scale photonic parts. They studied how these errors restrict the flexibility of quantum-dot units to carry out as designed, discovering the potential for a hundred-fold enchancment.

“A researcher is perhaps glad if one out of 100 units works for his or her first experiment, however a producer would possibly want ninety-nine out of 100 units to work,” Stavis famous. “Our work is a leap forward on this lab-to-fab transition.”

Past quantum-dot units, traceable requirements and calibrations underneath growth at NIST might enhance accuracy and reliability in different demanding functions of optical microscopy, reminiscent of imaging mind cells and mapping neural connections. For these endeavors, researchers additionally search to find out correct positions of the objects underneath examine throughout a complete microscope picture. As well as, scientists might must coordinate place knowledge from totally different devices at totally different temperatures, as is true for quantum-dot units.

Reference: “Traceable localization permits correct integration of quantum emitters and photonic buildings with excessive yield” by Daron A. Westly, Ronald G. Dixson, B. Robert Ilic, Marcelo I. Davanco, Samuel M. Stavis, Craig R. Copeland, Ashish Chanana, Kartik Srinivasan and Adam L. Pintar, 24 April 2024, Optica Quantum.

DOI: doi:10.1364/OPTICAQ.502464